Before the electric washing machine, a laundry load demanded four hours of manual labor and lots of hot water. Today your laundry choices make a big difference in cost and energy savings.

The typical household washes 300 loads of laundry a year. Got dirty clothes? Throw them into the washer with detergent, push the buttons, and they’ll come out clean a half-hour later. It seems simple enough, but today’s washer reflects a century of innovation, with many changes that made washing machines more efficient.

The introduction of home electricity in the early twentieth century led to an explosion of innovation that heralded the Second Industrial Revolution. By the 1920s, electric water heaters, air conditioners, washing machines and home furnaces had all been invented and were creating a mass market for home appliances. Among all these inventions, the washing machine may have done more than any other device to reduce household labor.

According to Susan Strasser, a University of Delaware American history professor and author of Never Done: A History of American Housework, “Mondays used to be the standard laundry day, and it could take all day.”

Before the washing machine’s invention, cleaning the family’s laundry demanded hot water, strong soap and washboards, paddles or plungers. It was backbreaking labor, mostly performed by women, and made only slightly easier by wooden tub washing machines invented in the 19th century. A single laundry load could take four hours. After the invention of the electric washing machine, it took only 41 minutes.

The original Thor washing machine.

In 1908, the Hurley Machine Company of Chicago, Illinois, introduced the first electric-powered washing machine, the Thor. According to washing machine historian and museum keeper Lee Maxwell, a Westinghouse motor and a mechanism made up of chains and pulleys turned a wooden drum 8 revolutions in one direction, then reversed the action. With the mechanisms exposed and no on-off switch, Thor could be a dangerous contraption that might snag the operator’s clothes or hair. Happily, manufacturers saw the opportunity for a better approach using stainless steel tubs with the mechanism enclosed.

In 1922, Thor 32 was “the last word in clothes-washing efficiency.” Household efficiency expert Mrs. Christine Frederick wrote You and Your Laundry, to explain new laundry techniques.

In 1911, Frederick Louis Maytag, an Iowa inventor, added an electric washing machine to his line of farm machinery, and in 1922, Maytag introduced the Gyrafoam, which boasted the first vaned agitator. Mounted in the bottom of the steel tub, it agitated to gently force water through the clothes. The gyrator and a rotating drum are design features that persist today in top-loading washing machines.

Washing machines caught on fast. Imagine - instead of washing clothes manually, you could put hot water in the machine, plug it in, and come back 20 minutes later to run the clothes through a wringer that did not need to be hand-cranked. By 1920, 1300 companies were producing washers. Maytag quickly took the lead, making a fifth of all washers in 1924. By 1927 Maytag had sold more than a million washers, an amazing number when you consider that the country’s entire population was 119 million.

Another significant innovation took place right before World War II when Bendix introduced the first automatic washer in 1937, followed by General Electric and Maytag models for the consumer market. Automatic machines had a timer and could autofill, rinse and spin-dry. Housewives could put their laundry into the machine and leave it unattended until the load was done, so by the 1950s, laundry had been reduced from a day-long ordeal to a couple hours.

In Evolving Households: The Imprint of Technology on Life, Economist Jeremy Greenwood argues for an even larger impact--that household appliances liberated married women from household tasks and led to a dramatic increase in their labor-force participation.

By the 1940s, the Whirlpool Surgomatic boasted “touch button” controls and featured external rollers to squeeze the water out of wet laundry.

Today’s washers boast a suite of automated features that make laundry relatively quick and easy. With 300 laundry loads a year, around 10% of a typical home’s electricity goes to washing and drying clothes, according to the Natural Resources Defense Council. You can reduce that cost by making smart choices.

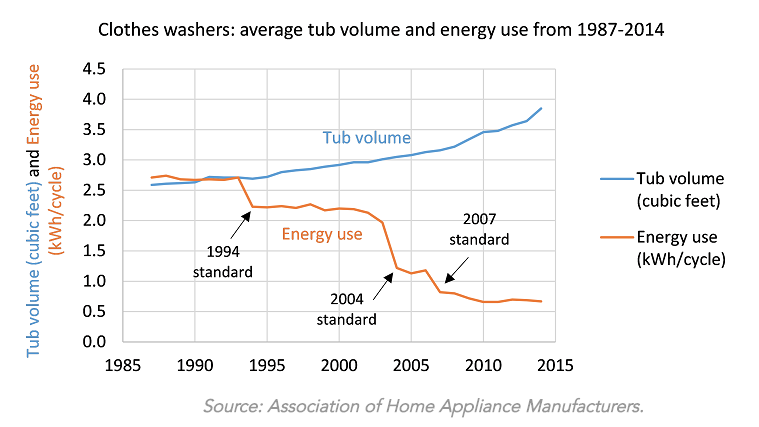

The government’s ENERGY STAR program has been very successful at reducing the water and energy cost of washing machines. In 1990, an average washer used 2.67 kilowatt hours (kWh) per cycle. Compare this to a typical washer in 2010, which consumed just .66 kWh per cycle – a 75 percent decrease. ENERGY STAR certified clothes washers use about 25% less energy and 33% less water than regular washers. Over the lifetime of the product, models that have earned the ENERGY STAR rating can save $380 in energy costs alone.

Is it time to update your washer? Washing machines that are 10 years old are significantly less energy efficient than current models. If you have a decade-old clothes washer, it's costing you, on average, $185 a year. When shopping for a new washer, do your research and look for both ENERGY STAR ratings and utility or state rebates.

Choosing more efficient washers has a big impact. If every clothes washer purchased in the U.S. were ENERGY STAR certified, it would save $3.3 billion in energy costs each year and avoid more than 19 billion pounds of annual greenhouse gas emissions. That’s like taking more than 1.8 million vehicles off the roads.

Here are some tips for reducing the energy waste of your weekly laundry load:

- If your washer is more than 10 years old, consider replacing it with an ENERGY STAR model that saves on both water and electricity.

- Wash large loads, rather than multiple small ones, and use cool water when you can. About 80-90% of the energy used by a washing machine goes to heating water.

- Check whether your water heater is working efficiently in order to minimize the cost of loads that require hot or warm water.

- Choose washing machines that rate the highest in water efficiency. Top loaders with agitators score relatively poorly compared to high efficiency top-loaders or front-loaders.

- Pay attention to how much moisture the spin cycle has removed from your clothes. Spin out as much water as you can before moving a load to the dryer (or hanging dry). Front loaders get more water out of clothes than the typical top loader.

- If your utility has variable rates, use electric washers and dryers when rates are low. If you have solar power, schedule laundry when the sun is shining to tap your clean power.

Looking to the future, washing machines may use a tenth of the water of current front loaders, translation into significant energy savings. The Xeros washing machine uses detergent and nylon polymer beads that absorb stains from laundry with as little as one gallon of water. Hotels are already using commercial Xeros machines, and the company is working with washing machine manufacturers to adapt their innovation for home use. Xeros has also innovated to capture plastic microparticles before they can leave the house in wastewater.

Clothes that come out of a washer with minimal moisture, as in the Xeros system, translate into lower drying costs, too. So what about innovations in dryer efficiency? Ultrasonic dryers will literally shake the water out of clothes using low energy, high frequency vibration created by piezoelectric transducers. They are 3-5 times as efficient as current dryers and get the job done in about a half hour. Scientists at Oak Ridge National Laboratory are working with General Electric to develop this innovative technology for the consumer market.

The washing machine is a daily labor saving appliance with more innovations on the horizon. So the next time you wish your laundry took less time, remember our foremothers, who devoted their Mondays to laundry.

Watch for our next blog post, where we’ll share insights about dryers from Sense’s data and an analysis by the Natural Resources Defense Council that points to the need for big improvements in dryer efficiency.

This article was written by Carol McGarry, Communications Director at Sense, who can remember her grandmother doing laundry in an old wringer washing machine and hanging it out to dry.