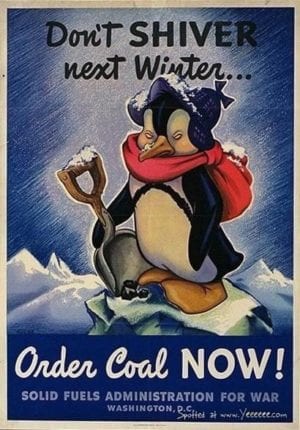

The home furnace is essential to our comfort as the days get shorter and temperatures dip below 50 degrees in many states. Today central heating keeps homes evenly warm in the chilliest weather, but just a century ago, heating was far less reliable and dirtier than it is today.

In the early part of the 20th century, coal was the standard of excellence for home heating in cool areas. The coal delivery truck dumped a load of dusty, black coal down a chute to a bin in the basement. From there, it was shoveled into coal-burning furnaces that heated the home. It was messy, but centralized heating was a big improvement over fireplaces.

In 1919, an inventor, Alice Parker, patented a central heating system that pulled cool air into a furnace where it was heated by natural gas combustion. The warmed air was carried by natural convection from the heat exchanger in the furnace, usually located in the basement, up through a network of ducts to each room of the house.

Although Parker’s invention wasn’t commercialized, it was the first of a new generation of furnaces that replaced coal with natural gas,

making home heating cleaner and more convenient.

Less than 20 years later, furnace design was updated again with the addition of an electric fan to blow the warm air throughout a house. Safe oil burners were invented in the 1930s. In 1940 more than half of U.S. homes still burned coal in their furnaces, according to the Census Bureau, but after World War II, most new homes were equipped with boilers or furnaces fueled by oil, propane, or natural gas. As fuel oil prices increased starting in the oil crisis of the 1970s, natural gas rose in popularity, especially in cold climates, and as natural gas prices have fallen, it’s become even more economical.

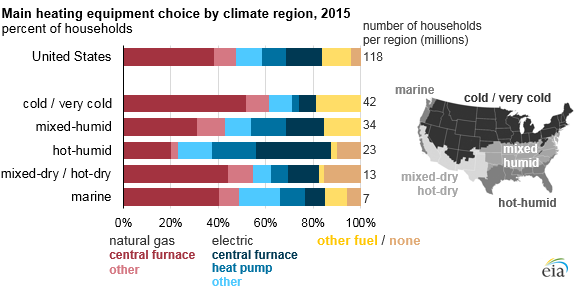

Today most homes are heated by natural gas furnaces, electric furnaces, or electric heat pumps, with choices varying by climate. In the hot, humid Southeast, where winters are mild, electric heating for cold days is common. In the cold Northern states, most homes are heated by central furnaces using natural gas. But the choices in individual homes vary widely. In its 2015 study of 5,687 households, the EIA observed more than 150 unique combinations of heating equipment and fuels.

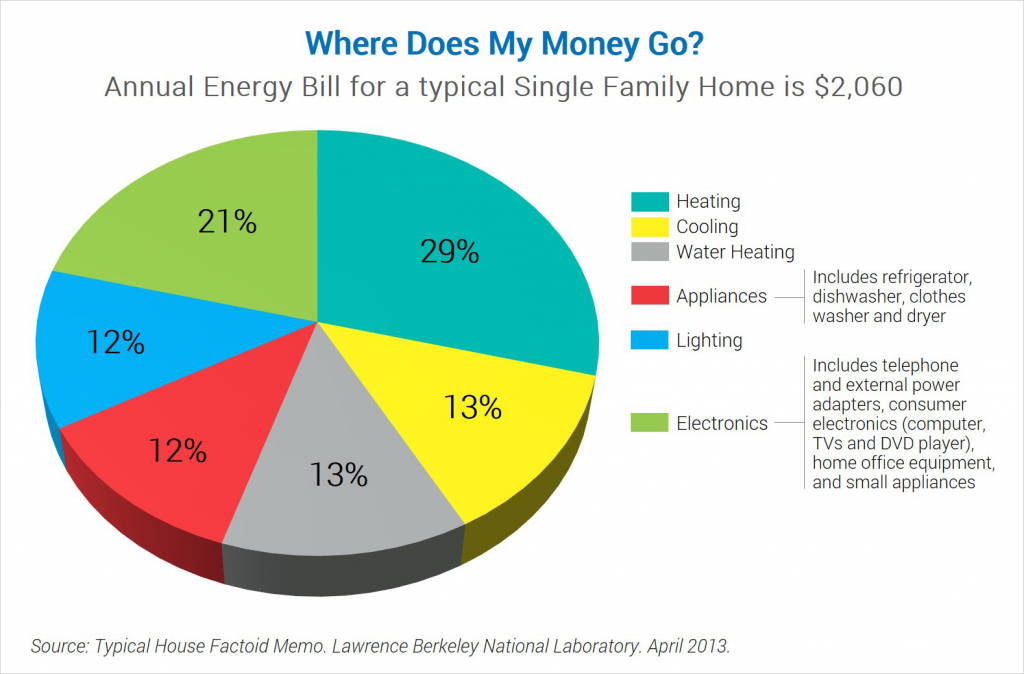

Home heating accounts for nearly a third of annual utility costs for a typical U.S. household, so reducing the operating costs of your heating system can make a significant impact on your utility bills. Luckily, innovations have begun to make home heating more efficient while lowering the impact on climate change.

Condensing Gas Furnaces

The basic parts of a gas furnace are the burner, heat exchanger, ductwork, and ventilation pipes or flue. Natural gas or propane is ignited in the burner and vented up a chimney flue or through ventilation pipes. The flames heat up a metal heat exchanger, which transfers its heat to cool incoming air. The furnace’s blower forces the heated air into the ductwork which distributes it throughout the home. As the warm air fills each room, the colder, denser air is drawn back into the furnace via return ducts in forced hot air systems, starting the process over again. All of this activity is controlled by the thermostat, which measures temperature in the rooms and tells the furnace to turn on or off.

For homes with steam or hot water heating, the gas furnace is paired with a boiler that heats up water, which is then pumped through pipes to radiators around the house.

Rather than venting the hot exhaust gases from the heat exchanger out the flue, condensing gas furnaces capture more of the heat in a second heat exchanger and return it to the home. The exhaust gas cools in the secondary exchanger, making carbon dioxide and water. The condensate drips out of the furnace into a catch basin

while cool gas vents out of the house through a pipe.

The efficiency of a furnace is measured by its AFUE (Annual Fuel Utilization Efficiency) rating. Whereas conventional gas furnaces have an AFUE rating of 80-83%, condensing gas furnaces can achieve the highest AFUE ratings of over 90 percent, with some reaching more than 98 percent.

Condensing gas furnaces have many other features to boost efficiency, including better insulated blower compartments, more energy efficient motors, higher efficiency air filters, heat recovery ventilators,

electronic ignition and electronic controls that modulate the gas burner. Because the exhaust gas is cool, a plastic vent pipe can carry it out of the house rather than requiring a chimney.

We calculated that if an old furnace used 80K BTUs with a 80% AFUE and it was replaced with a new furnace that delivers 96% AFUE, we’d be saving about $380 annually, so the payback period would be nearly 8 years for a furnace that costs $3000. You can calculate your annual AFUE savings with a new furnace here. Your savings depend on the system being correctly designed, installed, and operated.

Most utilities offer rebates for condensing gas furnaces that are ENERGY STAR certified. Be sure to research your utility’s rebates before replacing your furnace.

How Sense Tracks Furnaces

When the Sense home energy monitor detects a furnace, it’s tracking the components that use electricity: the igniter turning on, the blower motor running and the draft inducer fan circulating hot air into the ducts. While it doesn’t capture the energy consumed by burning gas or oil, it can tell you how the system components are working, which provides clues to its operation or malfunctioning.

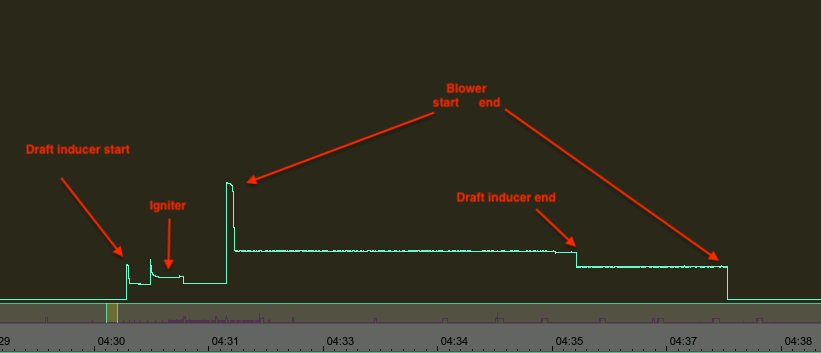

Here’s the energy signature of a furnace. Most working furnaces take 30 to 60 seconds for the draft inducer fan to start up, the igniter to turn on and then the blower motor to start, ready to blow warm air. By analyzing thousands of these sequences using Sense’s machine learning algorithms, we know that the timing of this sequence is very consistent for any particular furnace-thermostat pair.

But if the igniter doesn’t work, and the flame doesn’t spark, the furnace will turn off instead of starting the blower. The entire sequence is compressed into a shorter time frame, and since the flame didn’t ignite, the igniter will try again. In the Sense app, you’ll see a series of these energy patterns in sequence until finally the igniter does its job and gets the flame to ignite, triggering the complete cycle. This repetitive sequence can help you diagnose a failure in your ignition system. If you see this pattern, it’s time to schedule a service call to replace the igniter before it fails.

Without Sense tracking these events, you’d need to be quite attentive to your furnace. You might notice a long pause between the thermostat calling for heat and the blower finally turning on. Or if you sat by the furnace, you could hear the draft inducer motor turning on and off, and perhaps some clicking from the igniter. Typically, though, you’ll discover an igniter failure when the furnace stops working.

In the second part of this article, we’ll look at heat pumps.